Textiles and apparel

Our Department's researchers are developing advanced textile materials, technologies and products for a variety of applications, from biomedical devices, advanced composites for aeroplane-space technologies, personal protective devices, sportswear and smart e-textile wearables to digital technology platforms for novel fashion e-business models.

Research

Our researchers

The research starts from small to big scales: Graphene and 2D materials to form and/or functionalise fibres; fibre to form yarns, nonwovens and fabrics; yarns, nonwovens and fabrics to form composites, devices and apparels, buildings and airplanes with innovations in novel fibre spinning, fibre functionalisation, nonwoven fabrication, robotics, textiles and advanced composites, functional property measurements, smart textiles and wearables, body scanning and digital apparel.

Theoretical investigations into the sciences have developed advanced models, computational algorisms, databases and computer simulation software to link materials innovations with human biological needs to establish the technology platform to enable next generation of AI fashion and textile supply chain business models in big data environment.

Strengths and areas

The particular strengths and areas of the textiles and apparel theme include a number of research clusters: advanced textile materials: the fundamental sciences of how molecules and 2D materials such as graphene form fibres and then engineered into textile structures to achieve various functions to meeting the needs of human beings in terms of survival, healthcare, protection, physiological and psychological comfort, esteem and self-actualisations; textile composites and robotics; biomedical textiles; protective textiles; digital apparel engineering; smart e-textile fashion AI technology.

Advanced engineering solutions and technologies have been invented and developed to create novel textile materials and apparel products for making our lives more comfortable and exciting in our daily and professional activities, such as protective clothing for defence and policy forces, sports and outdoor ventures, exploration of space, building up sky high buildings, engineering world record breaking bridges, designing smart cars and high speed trains, manufacturing smart e-textile wearables and soft robots for future soldiers, producing textile implants and scaffolds to fix our sick or damaged organs and tissues, body scanning, as well as developing digital technology platforms for enabling fashion big data e-business models.

Case studies

Textiles and apparel research is making a significant societal impact, as demonstrated by our case studies:

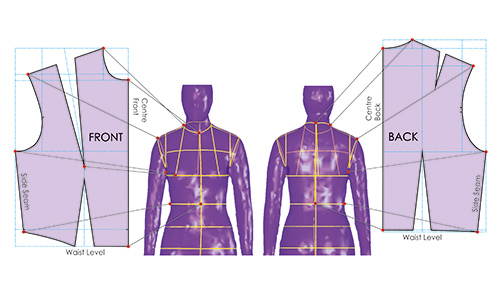

Generating size specific pattern blocks digitally: a foundation for customisation

As a key contributor to the digital apparel cluster, our apparel design engineering researchers are engaged in an EPSRC relationship incubator project. This explores capabilities for made-to-measure practices, developing open-source software for automatically creating pattern blocks that accurately reflect the size, shape and proportion of individuals. We use successful methods developed for the analysis of pattern-to-person relationships and 3D body scanning technology to create a platform for industry engagement using workshops. A key feature of this project is our public engagement using Size Stream body scanning technology, where anyone can book a scan to engage with both this project and with body scanning technologies potential.

Completion of the project will provide the framework for development of robust theory underpinning pattern block creation to be developed and explored. The automated pattern drafting software allows for clear theory linking the size, shape and proportion of individuals to pattern block shapes. In the longer term the project seeks to realise body-scanning-driven pattern development to be more focused within the clothing industry. Having developed the platform it will be possible to support SMEs looking to digitally create custom garments in a cost-effective way.

Key contacts

Robotics and textile composites

Prasad Potluri, Professor of Robotics and Textile Composites in the Department of Materials and the Director of Research at the Northwest Composites Centre / National Composites Certification and Evaluation Facility, works at the interface of robotics, textiles and advanced composites and has extensive industrial collaborations in technical textiles, aerospace, automotive, energy and defence sectors.

Over the last few years he attracted over £11 million funding for both fundamental research and collaborative research and development programmes. Funding sources include EPSRC, EU, TSB, AMSCI, DSTL and the US Air Force, as well as direct industrial funding.

He has been developing novel 3D textile preforming technologies through the EPSRC Future Composites Manufacturing HUB. Some of the novel technologies include 3D weaving of near-net preforms, complex braiding, robotic dry fibre placement, robotic tufting and stitching. Professor Potluri leads a large textile composites group consisting of 25 researchers working at doctoral and post-doctoral levels.

Smart functional e-textiles and AI fashion digital technology

Professor Yi Li - professor and chair in textile science and engineering in the Department of Materials - established the Textile Bioengineering Framework to conduct systematic research in textile thermal bioengineering, biomechanical engineering, sensory bioengineering and biomedical engineering.

Inventions from Professor Yi Li's team have been successfully commercialised. For example, the Moisture Management Tester won outstanding innovation and technology transfer awards (2010, Hong Kong), and has been sold to more than 30 countries and developed as the national testing standards in USA and China. The Nano Facemasks won a gold award (2005, Brussels) and has become the authorised product by Hong Kong Hospital Authority. The Fabric Touch Tester won a gold award (2013, Geneva) and has been sold to many countries. The high performance sportswear designed and developed by his team has been successfully transferred to industry and utilised to support elite athletes in major sports competitions around the world, including the 2008 Beijing Olympic Games and the 2012 London Olympic Games. A number of patents in smart e-textiles have been successfully transferred to industry. Anti-Heat Stress Clothing for Construction Workers won grand prize and a gold medal (2016, Geneva), Hong Kong Contraction Industry Council grand prize (2015), Charted Institute of Building International Innovation and Research Awards (UK, 2015), and has been transferred to Hong Kong construction industry and become a standard recommendation.

Current projects

Currently, Professor Yi Li is PI of two EU H2020 projects. The first, Welding of E-Textiles for Interactive Clothing, aims to develop novel e-textile structures, including transmission lines, sensors, actuators, microprocessors, personalised algorithms, on-body computing and user feedbacks in order to make a breakthrough towards development of interactive protective clothing, sports and biomedical devices that are able to monitor health, activity and position of the user in environmental risky situations using welding technologies.

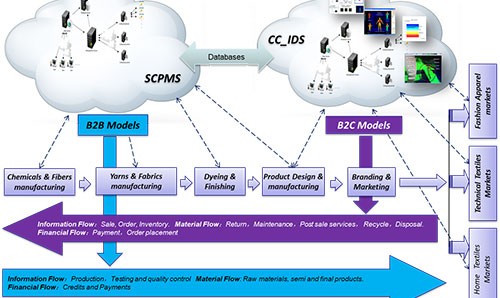

The second, Fashion Big Data Business Model, aims to create a digital technology platform for delivering small series innovative functional garment products through a EU-based local textile supply chain, meeting consumers' personalised requirements in terms of fashion and functional performances. This new supply chain will permit to get through the information channel from fabric materials to consumers via various processes, in order to dynamically organise design and production in the big data environment. This technology platform will integrate two interconnected knowledge based sub-systems (an interactive design system and a supply chain and production management system).