Facilities

Our range of facilities and equipment are key to supporting the quality of our research and teaching, and the needs of the industries that work with us.

From synthetic/textile fibre chemistry to materials processing and testing, our labs and physical spaces support the very latest in the characteriation and development of materials.

We are working hard to ensure we are able to provide safe access to these facilities in line with the latest government advice. The safety and wellbeing of our staff and students is our highest priority and we will be providing health and safety briefings as part of your induction.

Facilities used by the Department of Materials to support new research in textiles and materials science include:

-

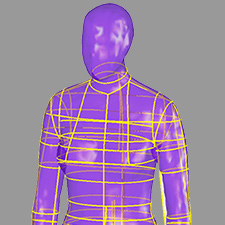

Body scanning

Body scanning can be used as a means to analyse the 3D body, its posture, proportions, and dimensions for product development or for the creation of information to guide and drive product development. This is currently one of the most effective tools for taking the human body into electronic environments.

We currently operate two body scanners a Size Stream device and a Tc2 NX16, both capture the 3D body and enable the development of files that can be analysed within the accompanying software or within other software. Both scanners provide customisable printed lists of measurement and can create 3D files as .obj, .xyz and .vrml.

Read more

-

International Centre for Advanced Materials

Recognising the critical dependence of the energy sector on new materials, the International Centre for Advanced Materials was set up by bp with a $100m investment in autumn 2012. Built upon a hub and spoke model this project brings together world-leading strengths of four universities, including The University of Manchester, to create an international centre of excellence in advanced materials research.

The facilities owned by its partner organisations cover many fields of activity that cut across institutional boundaries and academic disciplines. This equipment can be requested for use by members on active ICAM projects.

Read more

-

Dalton Cumbrian Facility

The Dalton Cumbrian Facility is the research base of The University of Manchester's Dalton Nuclear Institute, part of the National Nuclear User Facility.

It provides academia and industry with the opportunity to carry out high-end research in radiation science and nuclear engineering decommissioning, incorporating academic access to the active research facilities within the National Nuclear Laboratory Central Laboratory on the Sellafield site.

Read more

-

Electron Microscopy Centre

The Electron Microscopy Centre houses a suite of 22 electron microscopes, comprising 13 scanning electron microscopes, four dual beam focused ion beam microscopes (including one plasma focused ion beam) and five transmission electron microscopes.

Atomic resolution imaging and simultaneous chemical mapping are achievable with the FEI Titan G2 80-200 scanning transmission electron microscope and the centre also boasts a full suite of environmental cell and in situ testing capabilities.

-

Henry Royce Institute

The Henry Royce Institute is the UK national centre for advanced materials, bringing together more than £330 million of facilities distributed across nine partner institutions. With its hub at The University of Manchester, the Royce exists to accelerate innovation of advanced materials and to support the commercialisation of research.

The Royce focuses on nine advanced materials research areas: energy-efficient ICT, atoms to devices, chemical materials design, energy storage, advanced metals processing, nuclear materials, biomedical materials, 2D materials and material systems for demanding environments.

Read more

-

Manchester beamlines at Diamond

The University of Manchester has joined forces with Diamond Light Source, the UK's national synchrotron science facility, to produce a world-class imaging facility.

This allows researchers in a wide range of fields to create high-quality 3D images of samples, including engineering components, biomaterials, fossils, organic materials and energy devices such as fuel cells.

Read more

-

Materials Testing and Analysis Unit

We specialise in the determination of residual stress using X-ray diffraction (XRD), and in the measurement of retained austenite. We have performed residual stress measurements on samples ranging in scale from a few millimetres to several metres, and from a few grams to more than a tonne. Samples can be of a curved and / or complicated geometry, and residual stresses can be determined at the surface or sub-surface, using localised material removal if required.

Our team provides bespoke commercial services to the aerospace, automotive and other industries. We were the first laboratory to become UKAS accredited to ISO 17025 for this technique, and satisfy SABRe 3 (Supplier Management System Requirements) of Rolls-Royce plc, and have a portfolio of more than 130 other companies.

-

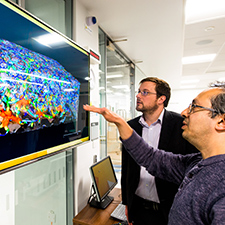

Multidisciplinary Characterisation Facility

The MCF addresses industrial needs by providing the means to study materials at a range of scales under demanding environments as close as possible to those experienced in service. By providing forensic analysis of the failure of materials, the MCF facilitates acceleration of a range of new materials.

Services provided include multiscale imaging, correlative imaging and multi-dimensional imaging (towards 4D). As part of the Henry Royce Institute, all MCF equipment is accessible to academics and businesses, is TRAC-listed and is supported by expert technical teams.

-

National Composites Certification and Evaluation Facility

The National Composites Certification and Evaluation Facility (NCCEF) is a UKAS-accredited testing laboratory with a full range of mechanical and physical testing and non-destructive evaluation equipment. Its remit is to work with companies in the supply chain to help them make the transition from metals to composites, understand the behaviour of composites and understand service performance, including failures.

Read more

-

National Graphene Institute

At 7,825sq m and with £13 million of equipment, the NGI enables academics and their industrial partners to work side-by-side on the development of new and exciting applications. Industry has a vital role to play in how graphene, the world's first 2D material, will be utilised - and research is nothing without development.

The NGI is equipped with 1,500m² of class 100 and 1,000 cleanrooms - which have an atmosphere more than a million times purer than air - and the latest technology for nanoscale and characterisation projects. It is a big space for big ideas.

Read more

-

Photon Science Institute

Located in the Alan Turing Building, the Photon Science Institute provides researchers from across the University with access to a suite of lasers and other instrumentation for undertaking innovative science research.

Laser facilities range from continuous wave, narrow linewidth and tuneable sources for high-resolution spectroscopies to ultrafast pulsed sources for probing dynamical processes.

Read more