Research with impact

The Department of Materials' research is highly diverse, but specifically addresses important societal problems such as energy sustainability, transport, biomedical implants and tissue regeneration.

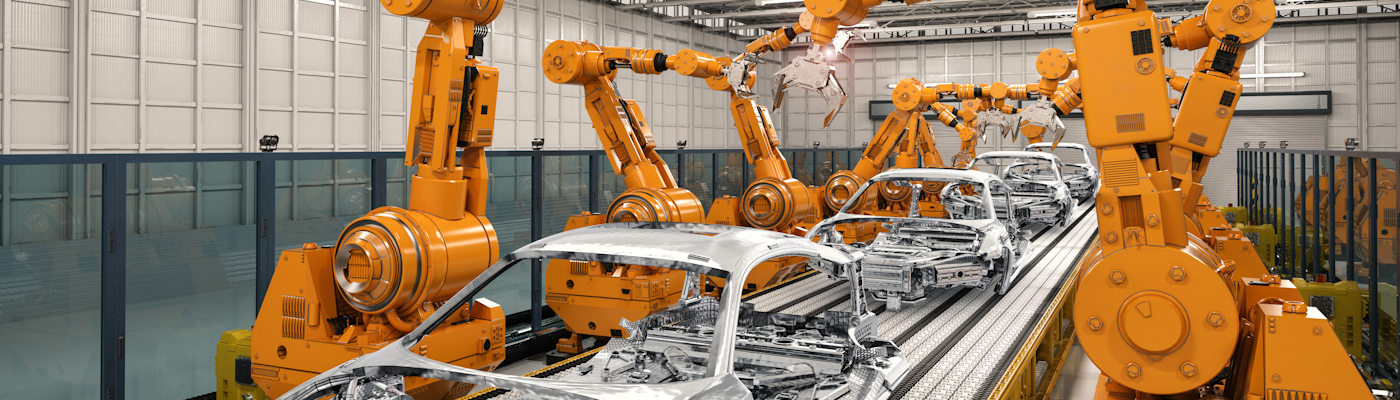

We are consistently one of the best externally funded schools in the University. We ensure that our research has a strong socially responsible focus; for example forming components from light alloys (aluminium, titanium and magnesium) is extremely important to sustainable transport because they can save over 40% weight compared to steel, and are far cheaper and more recyclable than composites.

Light alloy market

85% of the market in light alloys is in wrought products, formed by pressing or forging to make components.

This has led to rapid market growth, where light alloys are set to dominate the automotive sector. Remaining globally competitive in light metals technologies is also critical to the UK's aerospace and defence industries, which are major exporters. For example, Jaguar Land Rover already produces fully aluminium car bodies and titanium is extensively used in aerospace products by Airbus and Rolls Royce.

Healthcare research

In healthcare our researchers are investigating degeneration of the intervertebral disc (DIVD) and osteoarthritis (OA) resulting in chronic pain. They are major UK healthcare problems that are projected to grow as society ages, leading to reduced productivity and increased NHS costs. Double crosslinked microgels (DX MGs) are load supporting gels made from pre-formed microgel (MG) particles that can be linked together in vivo. MG particles are crosslinked polymer colloid particles that swell when the pH approaches the pKa of the polymer.